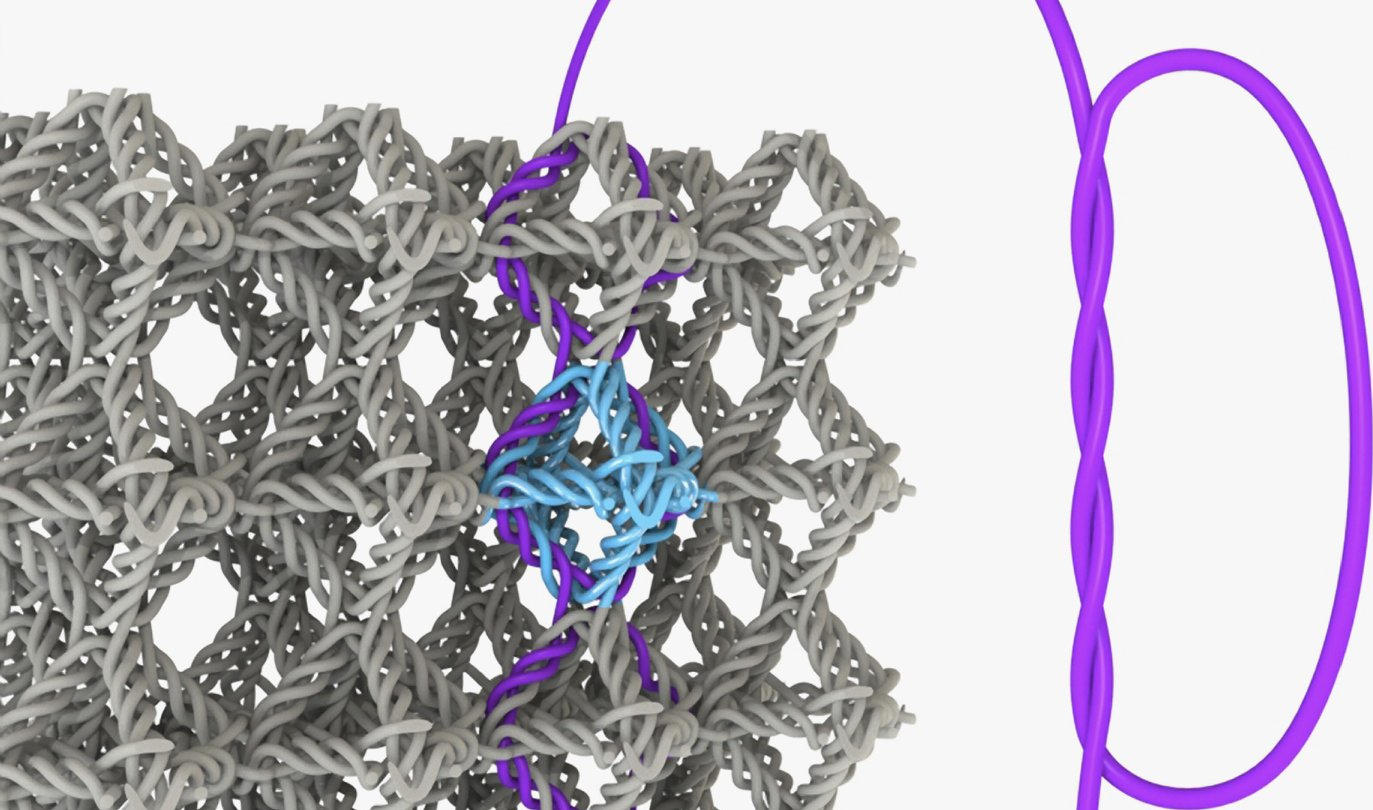

ポリマーから構築された複雑な材料は、個々のストランドが結び目ではなく絡み合っている材料など、複雑ではないが構造的に同一の材料よりもはるかに優れた引張靭性を示します。 クレジット: カリフォルニア工科大学

カリフォルニア工科大学のエンジニアは、多数の相互接続された極小ノードからなる新しい材料を作成することにより、ナノおよびナノ加工材料の分野で大きなブレークスルーを達成しました。

構造的に類似しているが連結していない素材と比較して、この新しい素材の結び目の存在は、損傷することなく元の形状に戻る前に、より多くのエネルギーを吸収し、より多く変形できるようにすることで、耐久性を大幅に向上させます。 これらの複雑な新しい材料は、その堅牢性、潜在的な生体適合性、および高い変形性により、生物医学および航空宇宙用途に応用される可能性があります。

材料の変形と引張強さの間の一般的なトレードオフを克服する能力 [the ability to be stretched without breaking] 柔軟性があり、耐久性が高く、極端な状況でも動作できるデバイスを設計する新しい方法を提供します」と、カリフォルニア工科大学の元大学院生である Widianto P. Moestopo は次の論文の筆頭著者です。[{” attribute=””>nanoscale knots that was published on March 8 in Science Advances.

Moestopo helped develop the material in the lab of Julia R. Greer, the Ruben F. and Donna Mettler Professor of Materials Science, Mechanics and Medical Engineering; Fletcher Jones Foundation director of the Kavli Nanoscience Institute; and senior author of the Science Advances paper. Greer is at the forefront of the creation of such nano-architected materials, or materials whose structure is designed and organized at a nanometer scale and that consequently exhibit unusual, often surprising properties.

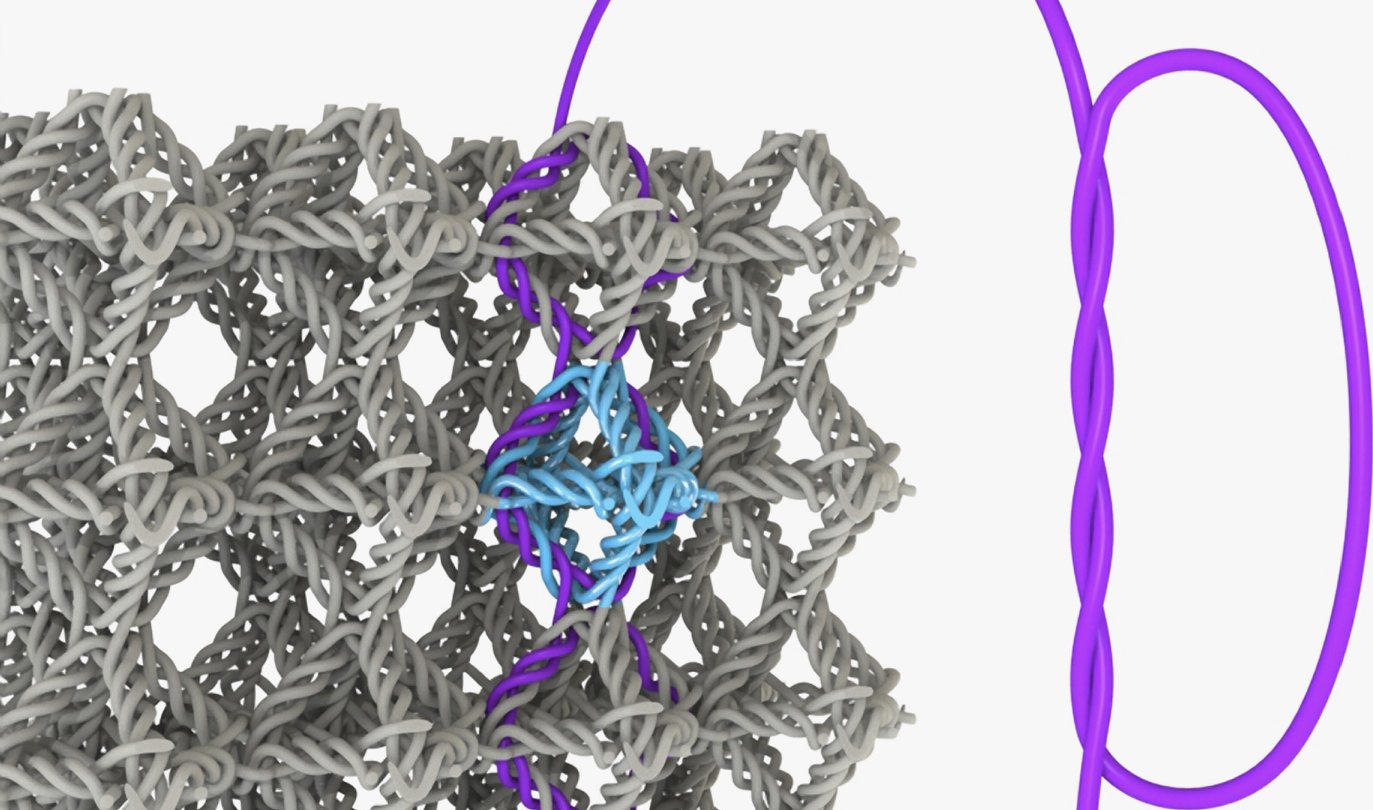

The tensile strength of a material constructed with microscale knots (left), compared to that of a material that lacks knots but is otherwise structurally identical (right). Credit: Caltech

“Embarking on understanding how the knots would affect the mechanical response of micro-architected materials was a new out-of-the-box idea,” Greer says. “We had done extensive research on studying the mechanical deformation of many other types of micro-textiles, for example, lattices and woven materials. Venturing into the world of knots allowed us to gain deeper insights into the role of friction and energy dissipation, and proved to be meaningful.”

Each knot is around 70 micrometers in height and width, and each fiber has a radius of around 1.7 micrometers (around one-hundredth the radius of a human hair). While these are not the smallest knots ever made—in 2017 chemists tied a knot made from an individual strand of atoms—this does represent the first time that a material composed of numerous knots at this scale has ever been created. Further, it demonstrates the potential value of including these nanoscale knots in a material—for example, for suturing or tethering in biomedicine.

The knotted materials, which were created out of polymers, exhibit a tensile toughness that far surpasses materials that are unknotted but otherwise structurally identical, including ones where individual strands are interwoven instead of knotted. When compared to their unknotted counterparts, the knotted materials absorb 92 percent more energy and require more than twice the amount of strain to snap when pulled.

The knots were not tied but rather manufactured in a knotted state by using advanced high-resolution 3D lithography capable of producing structures in the nanoscale. The samples detailed in the Science Advances paper contain simple knots—an overhand knot with an extra twist that provides additional friction to absorb additional energy while the material is stretched. In the future, the team plans to explore materials constructed from more complex knots.

Moestopo’s interest in knots grew out of research he was conducting in 2020 during the COVID-19 lockdowns. “I came across some works from researchers who are studying the mechanics of physical knots as opposed to knots in a purely mathematical sense. I do not consider myself a climber, a sailor, or a mathematician, but I have tied knots throughout my life, so I thought it was worth trying to insert knots into my designs,” he says.

Reference: “Knots are not for naught: Design, properties, and topology of hierarchical intertwined microarchitected materials” by Widianto P. Moestopo, Sammy Shaker, Weiting Deng and Julia R. Greer, 8 March 2023, Science Advances.

DOI: 10.1126/sciadv.ade6725

The study was funded by the National Science Foundation through Moestopo’s Graduate Research Fellowship Program, Caltech’s Clinard Innovation Fund, Greer’s Vannevar Bush Faculty Fellowship, and the Office of Naval Research.

「主催者。ポップカルチャー愛好家。熱心なゾンビ学者。旅行の専門家。フリーランスのウェブの第一人者。」

/cdn.vox-cdn.com/uploads/chorus_asset/file/25592468/2113290621.jpg)

More Stories

スペースX社がスターシップロケットの打ち上げ準備中、昼夜を問わず火花が散る

二つの大陸で同一の恐竜の足跡を発見

NASAの探査機パーサヴィアランスが火星の火山クレーターの縁に向けて急登を開始